Development

#MakeEvosGreatAgain

We're working on a few other things for the Evo 4-9 platform. This section is some general information and rambling, feel free to comment or email through your ideas, thoughts and feedback.

Oil Pump - The Villain of the 4G63

The oil pump (front cover) gets a tough time as the scapegoat of the 4G63 oil pressure problems. It's our opinion that the oil pump damage mostly comes from oil surge. When the pump picks up air, the oil film protecting the oil pump gears in the aluminium housing degrades and allows for metal-on-metal contact. This results in the slow degradation of the oil pump and eventual catastrophic damage.

Big damage to the oil pump for a range of reasons, the primary reason being oil surge (pumping air). Stiff aftermarket valve springs and cambelts combined with oil surge will quickly damage the oil pump. Also incorrectly tensioned (over tensioned) cambelts accelerate wear and failures. The main drive gear shaft is steel and the housing is plain aluminium, there are no bearings. Once the oil film degrades it starts to destroy itself rapidly. Add some high RPM (9000+) use and it's a recipe for disaster.

*NOTE - stub shaft has no damage in this example.

Main drive oil pump gear is 33% faster than engine rpm.

Balance shaft (or stub shaft) is 100% faster (double) than engine rpm.

E.g. at 9,000rpm engine speed, the balance shaft is spinning at 18,000rpm.

Oil Pump Oil Flow

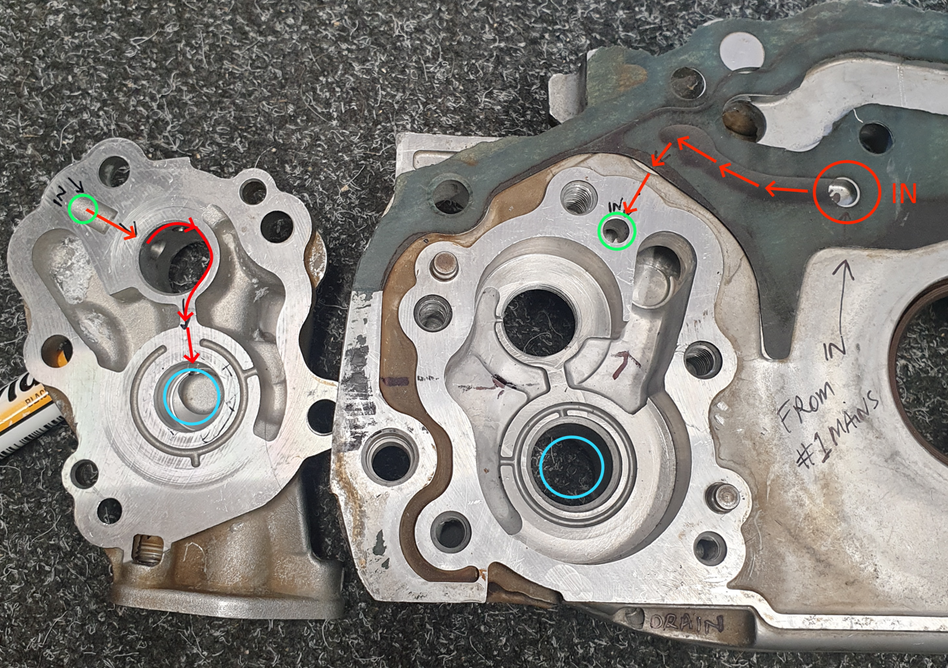

The 4G63 oil pump receives it's oil from the #1 mains gallery. The oil flows across the front cover and eventually into the "Driven Gear Shaft" (Green circle on pic).

This is why it's important to use a stub shaft with a groove cut into the centre, so the oil can flow to the next section.

The last area for the oil to reach is the shaft that fails the most, the "Drive Gear Shaft" which is directly spun by the cambelt. These are plain aluminium bushings/bearings, there no needle or ball bearing here.